about

vision

We envision a world where plastic waste is eliminated and no longer polluting our environment.

mission

We upcycle plastic waste and use it to improve the quality and cost of asphalt.

-

Our staff and partners have immeasurable value, and we strive to achieve win-win scenarios in the best interest of all parties.

-

Our integrity is not to be compromised, our word is our bond and bonds are our livelihood.

-

Our success lies in a solutions-based approach that keeps an eye on the bigger picture.

-

Our collective minds remain in a constant state of readiness to grow, change, and excel at all levels.

core values

who we are

Mark McCollough

CEO

Industry Experience

Construction Management

Startup Growth

Marie Logsden

CSO

Business and Growth Strategy

Political Strategist

Brand/Marketing/Comms

Chris Wacinksi

CTO

Process Engineer

Product Manager

Plastics Manufacturing

Adam Farmer

COO

Engineering Manager

Mechanical & Electrical

Design & Optimization

“Buck” Matt Buckstein

Director of Special Projects

Human Resources

Strategic Leadership

Process Improvement

AWARDS

ELVALOY™ RET by The Dow Chemical Company and Driven Plastics

Driven Plastics and Dow Chemical 2023 Winner Sustainability Category

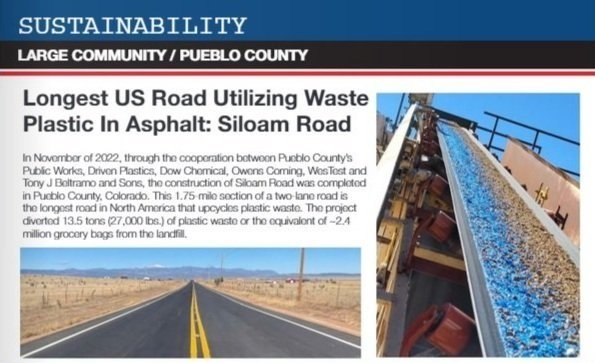

American Public WorKs Association Colorado Award for Sustainability

what we do

Our system requires three components for success.

First, our community-based process works to identify difficult to recycle plastic waste and works with partners to divert it from landfill and ship it to our plant.

Second, we process the material locally add the proprietary activator and create safe, meaningful, and good paying jobs for the community. The facility requirements for our system are readily available and do not require heat, water, or harsh chemicals in production.

Third, we work with a local hot-mix asphalt contractor and supplier to manufacture and construct projects with the new asphalt design.

Our design process for the hot-mix follows the traditional design process for binder and mix design. We can meet or exceed mix design parameters for all polymer modified asphalts.

Our system can be used in most circumstances with no modification to the asphalt hot-mix plant. If the right feeder is not present, we provide a simple add on device that can be integrated into the control system of the asphalt hot-mix plant.

On the job site, our material handles just like other asphalt installs requiring no change to equipment or process.

in the news

Driven Plastics to present at AMAP in a joint presentation with Owens Corning and Dow Chemical.

Driven Plastics featured in a County of Pueblo video

more news

Driven announcement of Pueblo facility

Pueblo's newest company converts plastic waste into asphalt product (chieftain.com)

WATCH - New business brings green jobs to Pueblo (kktv.com)

R&D World 2022 R&D 100 winner for Mechanical/Materials category:

Edison Awards 2023 Gold Winner